A Master Control Reset (MCR) instruction is an output instruction. MCR instructions are always used in pair.

The paired instructions cause the PLC to enable or inhibit a zone of ladder logic program outputs according the application logic. The zone being controlled is known as the MCR zone control. It begins with the rung that has the first MCR instruction. The MCR zone ends with the rung that has the second MCR instruction only.

Using this instruction, we can disable all the outputs at the same when MCR condition goes off.

Two MCR instruction are used to perform the function, One is to start the MCR zone with input condition as must and another one is to end the limit area.

An input condition like Emergency switch is programmed on the rung of the first MCR to control rung logic continuity. When the rung goes “false” all non-retentive outputs within the controlled zone are disabled. When the rung goes “true” all rungs are scanned according to their normal rung conditions.

No need to give any condition for closing MCR zone.

Let’s study the working of MCR using example,

Master Control Reset

Introduce MCR zone in automatic bottle filling system.

Problem Logic

Step Conditions:

Start and Stop PB is used to start and stop the process.

MCR zone need to activated to start the process

Start is pressed Conveyor starts moving until the Proximity Sensor is ON.

Then solenoid valve is open for 5s. After 5s Conveyor should start moving.

The above process should continue unto 3 bottles.

Process should continue still stop push button pressed.

In any emergency case, MCR condition goes off, all output disabled irrespective of its input.

List of Inputs and Outputs

If MCR Goes Off :

see the below same ladder logic when the Master Control Reset (MCR) instructions becomes de-activated.

Program Description

RUNG 0000

Latching rung to operate the system through Master Start and Stop PB.

RUNG 0001

MCR zone is introduced with input condition.

RUNG 0002

To turn ON Conveyor motor, memory bit (B3:0/1 ) is used .

RUNG 0003

To turn on Conveyor motor using memory bit of start latching PB and B3:0/1, it will automatically turn off when B3:0/2 turns on once Proximity sensor activates. Timer done is connected in parallel to turn conveyor motor ON again.

RUNG 0004

Proximity sensor output saved in memory bit to use in previous rung.

RUNG 0005 and Rung 0006

To store the status of proximity sensor B3:0/3 is used, Comparator block is used to compare counter accumulator value to stop the process once three bottle process had filled.

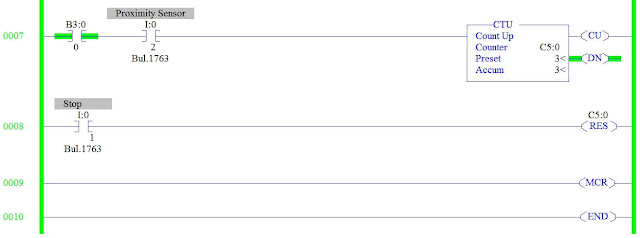

Rung 0007

To count the number of bottles, proximity sensor is given to up counter with preset value sets to 3.

RUNG 0008

Stop input is given to reset the counter.

RUNG 0009

MCZ zone is ended here.

Conclusion:

The above example of MCR explanation for simple bottle filling system. It may vary from real time.

Comments

Post a Comment