Learn how to create login security for InTouch SCADA programs using multi-level users with a specific username and password.

InTouch SCADA Security

Security is an essential parameter in every industry. Who can have access to the data and how much a person can see data, everything you can control within SCADA software.

Let’s learn how to activate the security feature in InTouch SCADA.

Step 1:

Open InTouch. Create a new project and enter an animation environment.

Step 2:

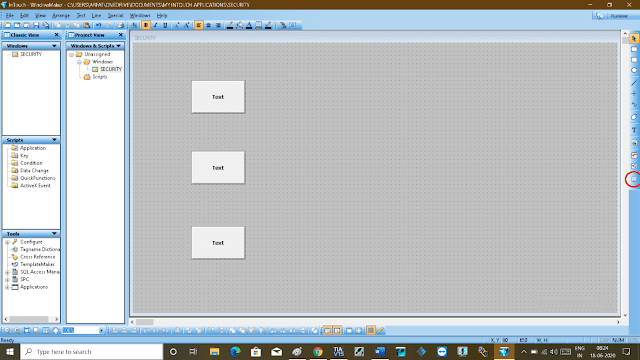

Now I will take an example in which I have a three-persons, one is a manager, the second one is an engineer and the last one is an operator.

I will take three buttons to represent each person and will use three lamps in which I define who can have access to activate the lamp.

To add a button, click on the last icon as shown in the below window.

Do right click on each text button to give a name.

Step 3:

I have added text to the buttons.

Step 4:

Now add three lamps.

Step 5:

To activate security go to “special” then “select security type” and select “InTouch”.

Step 6:

Then go to “special” and in security click on “log in”.

Step 7:

The following window will pop up. Give a name and password to add user access.

The default user name is “administrator” and the password is “Wonderware”.

Step 8:

Then go to “special” and click on “configure user”.

Step 9:

The following pop up will open.

Add user name, password, and access name for a user that we want to configure.

Click on “Add” to add a user.

Step 10:

Now Double click on “manager” and select “disable” option.

Step 11:

In the below pop-up, give an access level “1” (as per we gave into the security window). Hit “ok” to proceed.

Do the same to the other two buttons.

Also, give a tag name to the lamp.

Step 12:

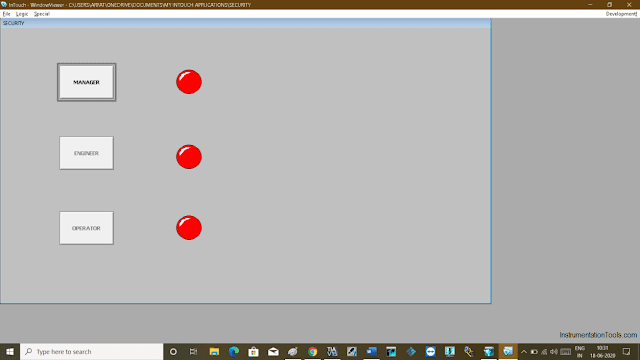

To test the animation, go to the runtime window. As you can see all three buttons are disabled.

Step 13:

Now login to access the first lamp which relates to the manager. Login and do follow as shown in the below window.

Step 14:

Give the user name and password which you have created earlier, Hit ok to enable the manager button.

Comments

Post a Comment